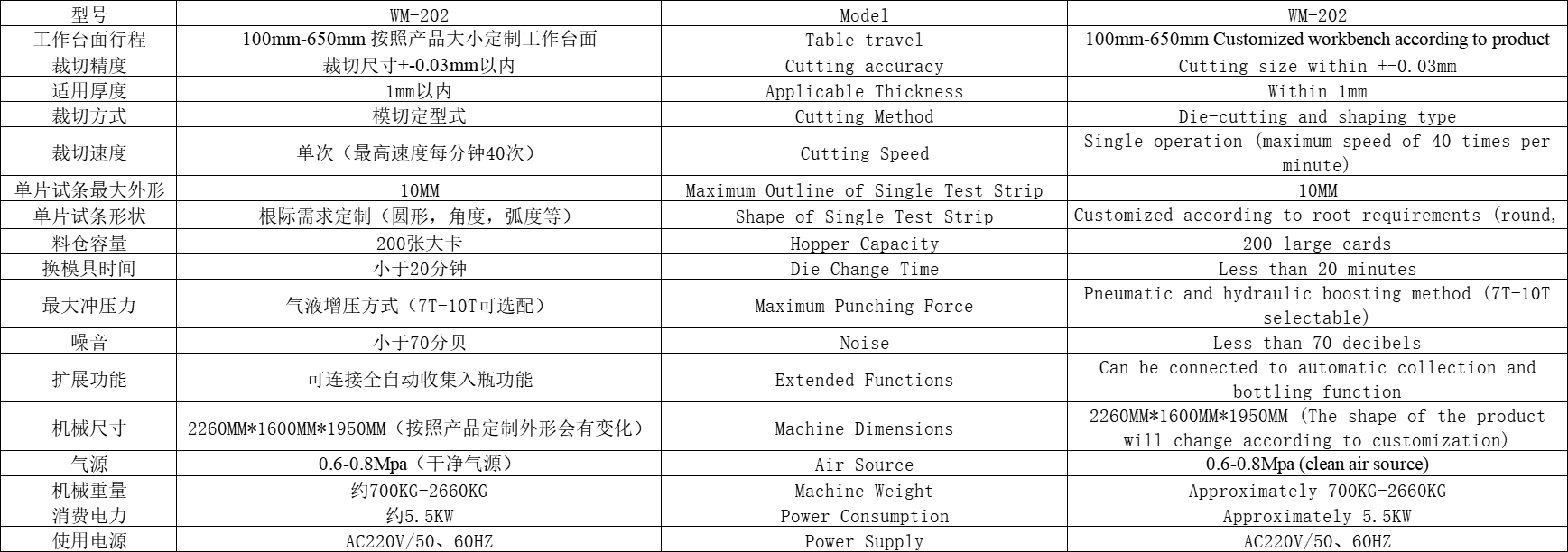

1. This equipment is a high-precision die-cutting device developed specifically for manufacturers of blood glucose test strips with non-standard shapes.

2. The equipment adopts hole positioning, making it an ideal production auxiliary device for manufacturers.

3. Custom molds can be produced for different shapes, enabling one-time forming of 25 to 50 pieces.

4. The molds utilize imported Japanese SKD-61 alloy material combined with vacuum heat treatment, ensuring excellent wear resistance. Surface titanium coating treatment can also be customized.

5. The equipment features automated loading and unloading, with automatic waste collection after die-cutting.

6. Optional CCD inspection function can be added to automatically reject defective products and perform functions such as automatic counting for bottle filling.

1. This equipment is a high-precision die-cutting device developed specifically for manufacturers of blood glucose test strips with non-standard shapes.

2. The equipment adopts hole positioning, making it an ideal production auxiliary device for manufacturers.

3. Custom molds can be produced for different shapes, enabling one-time forming of 25 to 50 pieces.

4. The molds utilize imported Japanese SKD-61 alloy material combined with vacuum heat treatment, ensuring excellent wear resistance. Surface titanium coating treatment can also be customized.

5. The equipment features automated loading and unloading, with automatic waste collection after die-cutting.

6. Optional CCD inspection function can be added to automatically reject defective products and perform functions such as automatic counting for bottle filling.