In the field of in vitro diagnosis (IVD), the types of test strips are becoming increasingly abundant. From blood sugar strips to HB strips, from urine strips to colloidal gold bars, different products have different requirements for cutting processes. As a company deeply involved in automation equipment, Jurui Automation Equipment Co., Ltd. has accumulated experience in cutting multiple types of test strips, and continues to optimize the process and tool design, bringing high-precision, high-adaptability and customizable cutting solutions to customers.

Today, we will take everyone into the "world of test strip cutting" to see how Ju Rui helps reagent companies achieve precision product manufacturing through rich cutting experience and professional tool configuration. The cases described below are all the completion of the hob cutting process to ensure the efficiency of the production process.

1. Different test strips, different challenges: Ju Rui's multi-scene cutting experience

We roughly divide test strips into the following categories. Based on their structure and material characteristics, Jurui has accumulated rich processing experience:

1. Blood sugar strips, HB reagent strips: mainly rectangular cut

This type of product is common in single-layer card structures. The cutting process is mainly rectangular cutting strips and does not support special-shaped cutting.

Behind the seemingly simple rectangular cutting, there is a hidden way to adapt materials: different membrane materials, mat materials and support layers all need to match knives with different sharpnesses and angles.

Jurui selects knives based on material characteristics, effectively reducing common problems such as "constant cutting","rough edges" and "creases", and ensuring the consistency and pass rate of each product.

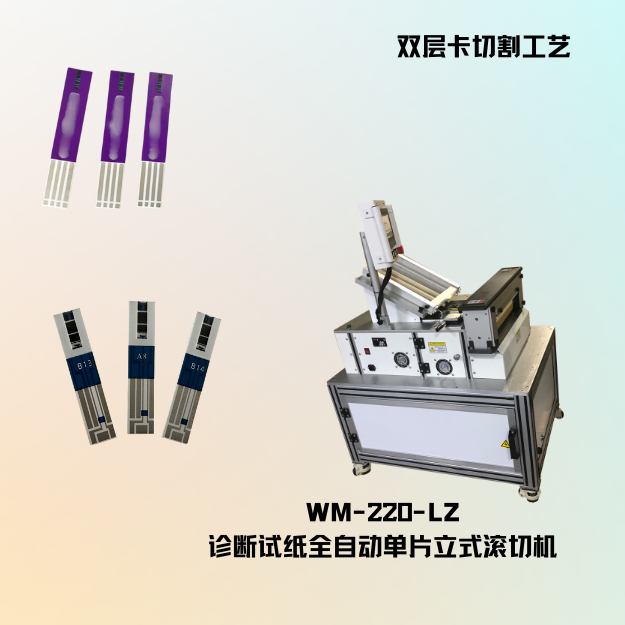

2. Double-layer card products: high-strength tools and precision auxiliary systems

The double-layer card structure is more complex, which puts forward higher requirements on the tool.

In order to ensure that the incision is free from burrs, indentations, and deformation, we use special knives with high toughness and hardness, and match them with rubber scrapers to accurately protect the color block areas from falling off or being squeezed and deformed.

This type of process particularly tests the pressure control of the equipment and the rigidity of the tool, which is the advantage of Jurui.

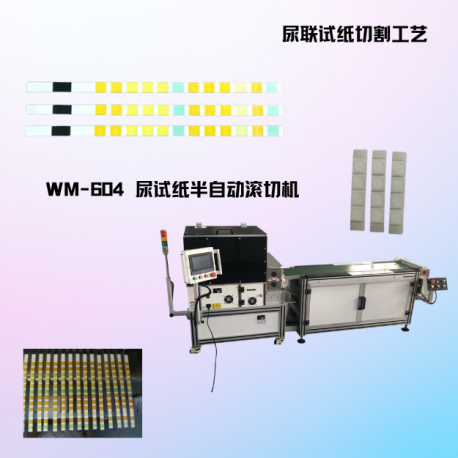

3. Plain knife cutting of urinary products: both sharpness and protection WM-604(606 fully automatic)

When cutting the urine coupling strip, we use a flat knife structure with a rectangular cross-section of the blade, which has both sharpness and stability.

In order to prevent damage to the color block area, the equipment is also equipped with a stainless steel mirror scraper to effectively prevent the test paper from being deformed or the color block falling off.

This high-precision and protective cutting solution has been verified by customers in multiple urine joint projects.

4. Challenges of thick and brittle materials: Film cutting can also be easily handled

For some thicker or fragile membrane materials, such as the special membrane structure in urinary products, Jurui still has the ability to handle.

Through our self-developed tool structure and pressure control system, we effectively overcome the problems of fragile and deformed materials, and achieve the unity of precise cutting and stable efficiency.

5. Colloidal gold test strip: cut with a single-sided rolling cutter, and passed the small batch verification

At present, we use a single-blade cutting solution for cutting colloidal gold test strips. Although it has not yet been fully rolled out in large-scale applications, customer trial feedback shows that the cutting effect has met its technical requirements and can be customized according to market demand in the future.

2."A good knife" is the soul of all cutting processes

Many people think that cutting is just a mechanical action, but in fact, 70% of the "cutting well" depends on the selection and design of the tool.

At Jurui, we customize and match tool structures based on factors such as thickness, hardness, number of layers, surface treatment process, etc. of different materials: including multiple types such as single knives, flat knives, and special-shaped knives, and the angle and sharpness of each tool., and the selection of materials are conclusions reached by the technical team after repeated verification.

Exquisite cutting technology keeps the reagent strips neatly arranged when they are discharged during the cutting process. On this basis, we have developed automatic reagent strip cutting and barrel loading equipment, such as the WM-211 series of fully automatic equipment, which can realize the equipment. Automatic feeding, automatic cutting → cutting effect detection → reagent strip counting → reagent strip loading and other subsequent processes.

In addition, in order to reduce cutting deviation caused by cumulative errors, we have integrated an automatic correction system and a high-precision feeding structure into the equipment to ensure that the size and position of each reagent strip meet the standard during long-term production.

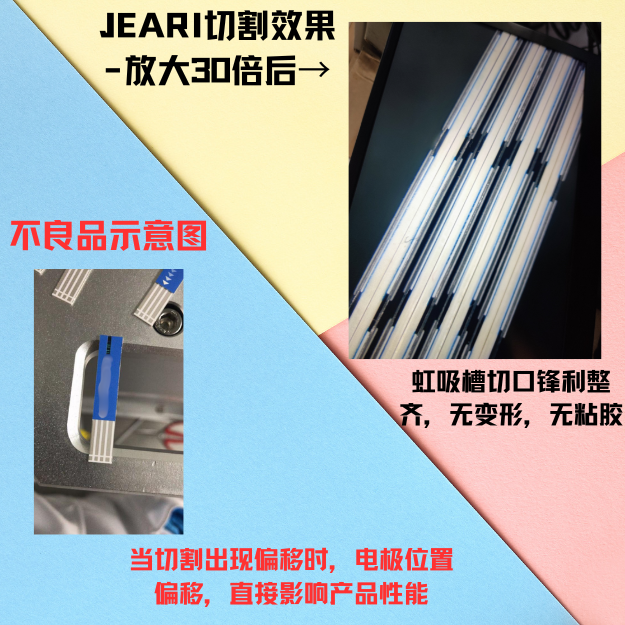

3. From "constant cutting" to "precise cutting": What we solve is not just superficial problems

Common pain points in the cutting process include:

·Continuous cutting: The material is not completely cut through, affecting efficiency and yield

·Fractures and creases: affect product appearance and even the compatibility of subsequent processes

·Tangent deviation: In electrochemical products, cumulative errors directly affect the accuracy of signal detection

These problems cannot be solved by "hard cutting" and require dual guarantees from equipment design and process control. Jurui not only provides equipment, but also helps customers analyze problems, adjust processes, and even develop special tools and components for special needs.

4. We can develop what we don't have. If you need it, please send samples.

Test strip products on the market are changing with each passing day, and their materials and structures are constantly changing.

Jurui always maintains an open and cooperative attitude. Customers are welcome to send test strip materials to us for evaluation. We will provide the most suitable cutting solution.

Whether it is a standard card structure, a new laminated membrane structure, or special materials or special-shaped cutting needs--

"When you encounter cutting problems, please hand it to Ju Rui to solve them."

This is our commitment and the driving force for us to keep moving forward.

Contact for sending cutting samples for evaluation: Angel 136 7198 8005 Rhea 137 0187 5812